Hastelloy N-(Hastelloy N)(UNS N10003)

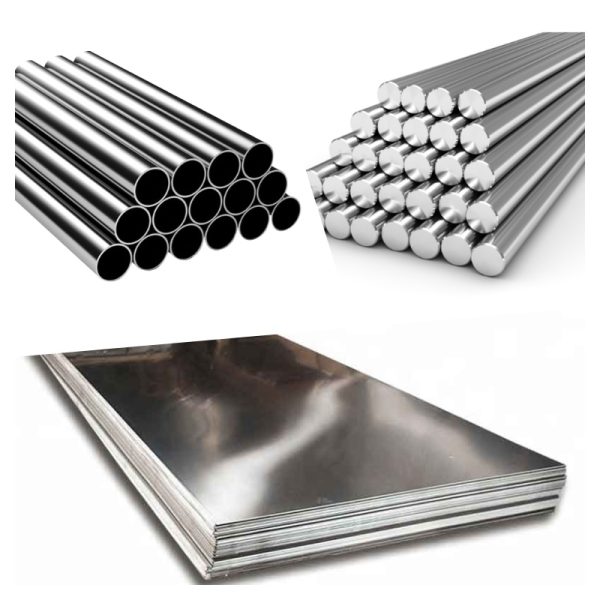

Available forms of Hastelloy N

– Round bars、wire、forgings

– sheet、plate

– seamless pipe and tube、welded pipe and tube

– pipe fittings and flanges

– non-standard customised parts

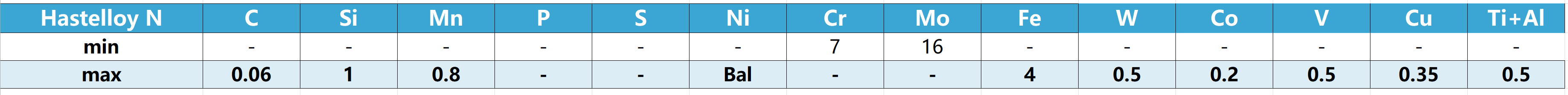

1.Hastelloy N CHEMICAL COMPOSITION

2.Hastelloy N Introduction

HASTELLOY® N alloy (UNS N10003) is a nickel-base alloy. container material for molten fluoride salts. It has good oxidation resistance to hot fluoride salts in the temperature range of 1300 to 1600°F (704 to 871°C).

3.Hastelloy N MAJOR SPECIFICATIONS

4.Hastelloy N PHYSICAL PROPERTIES

| Density [g/cm3] | 8.78 |

| Melting point [oC] | 1300-1400 |

5.Hastelloy N CHRACTERISTICS

① Nickel is one of the main components, which can improve the strength and resistance of steel and improve hardenability. When the content is high, some physical properties of steel and alloys can be significantly changed, and the corrosion resistance of steel can be improved.

②Chromium is also one of the main components, which can improve the hardenability and wear resistance of steel, and can improve the corrosion resistance and oxidation resistance of steel.

③As one of the auxiliary alloys, copper has a prominent role in improving the atmospheric corrosion resistance of ordinary low-alloy steels, especially when used in conjunction with phosphorus. The Monel system is essentially a nickel-copper alloy.

④Molybdenum, as one of the auxiliary alloys, can obviously improve the hardenability and thermal strength of steel, prevent temper brittleness, and improve remanence and coercive force. Hastelloy is essentially a nickel-molybdenum alloy.

6.Hastelloy N HEAT TREATMENT METHODS AND CHRACTERISTICS

①Solid solution strengthening is an important method of metal strengthening, which improves the strength and hardness of the metal by forming a solid solution. When the solute content is appropriate, the strength and hardness of the material can be significantly improved, while the plasticity and resistance are not significantly reduced. is its greatest characteristic.

②Aging enhancement is divided into artificial aging and natural aging. Natural aging strengthening is to strengthen the alloy in the process of placing at room temperature; while artificial aging strengthening is to strengthen the alloy in the process of low temperature heating. Both are conditional on solid solution strengthening, both to advance alloy strength.

③ Bulk strengthening is conditional on aging strengthening, and the purpose is to strengthen the alloy. The addition of cobalt, tungsten, molybdenum and other elements makes the alloy obtain high yield strength.

④ Grain boundary strengthening occurs because the grain boundary of the alloy is a weak link at high temperature, and the addition of trace amounts of boron, zirconium and rare earth elements can improve the grain boundary strength.

⑤ Annealing: The annealed state is the basic condition of the furnace. The essence is to transform high-speed steel from austenite to pearlite. The function is to reduce the surface hardness of the high-speed steel and improve the plasticity to facilitate cold deformation processing such as cutting; to make the composition of the steel uniform, to improve the performance, and to prepare for further heat treatment; to eliminate stress to prevent deformation or cracking.

7.Hastelloy N TYPICAL APPLICATION AREAS

Molten Fluoride Salt Container