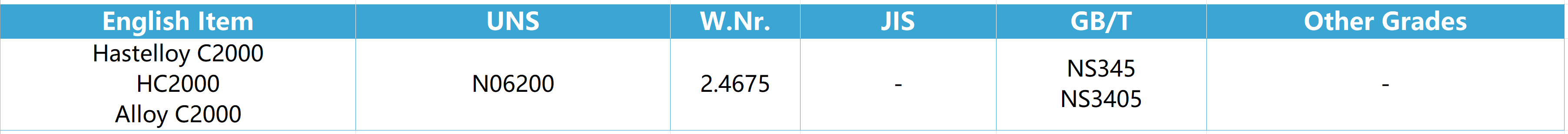

Hastelloy C2000-(Hastelloy X )(UNS N06002) (W.Nr. 2.4665)

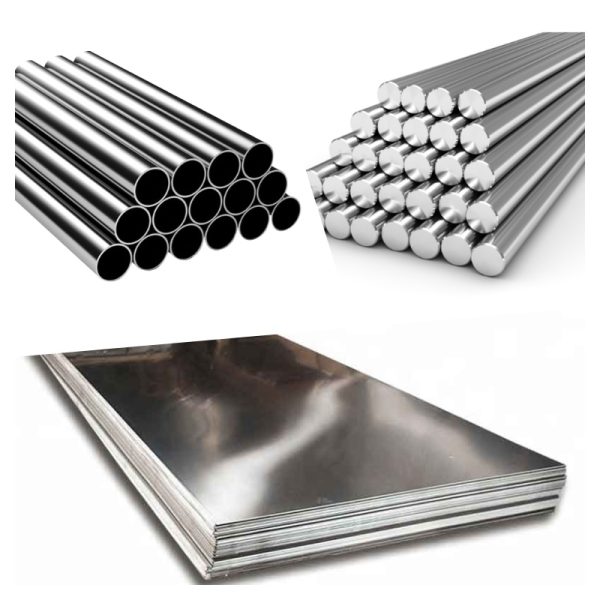

Available forms of Hastelloy C2000

– Round bars、wire、forgings

– sheet、plate

– seamless pipe and tube、welded pipe and tube

– pipe fittings and flanges

– non-standard customised parts

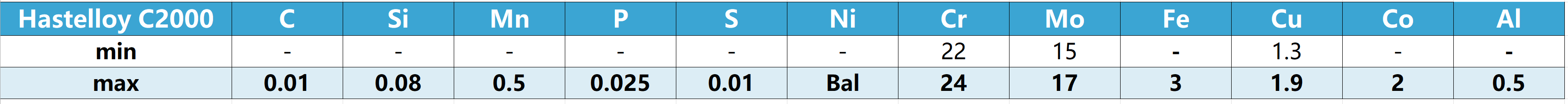

1.Hastelloy C2000 LIMITING CHEMICAL COMPOSITION, %

2.Hastelloy C2000 Introduction

HASTELLOY® C-2000® alloy (UNS N06200) is unique among the versatile nickel-chromium-molybdenum materials in having a deliberate copper addition. This provides greatly enhanced resistance to sulfuric acid. It also has a high chromium content, to maximize its resistance to oxidizing chemicals and process streams contaminated with ferric ions and dissolved oxygen.

Like other nickel alloys, it is ductile, easy to form and weld, and possesses exceptional resistance to stress corrosion cracking in chloride-bearing solutions (a form of degradation to which the austenitic stainless steels are prone). It is able to withstand a wide range of oxidizing and non-oxidizing chemicals, and exhibits outstanding resistance to pitting and crevice attack in the presence of chlorides and other halides.

3.Hastelloy C2000 MAJOR SPECIFICATIONS

4.Hastelloy C2000 PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density [g/cm3]

……….8.5

Melting point [℃]

……….1328-1358

5.Hastelloy C2000 Metallographic Structure

Hastelloy c2000 alloy has a face-centered cubic lattice structure, and its chemical composition ensures metallographic stability and resistance to sensitization.

6.Hastelloy C2000 Corrosion Resistance

Hastelloy C2000 is a material designed to resist more aggressive chemicals, including sulfuric acid, hydrochloric acid, and hydrofluoric acid. Unlike the previously optimized Ni-Cr-Mo alloys which are only resistant to oxidizing or reducing acids, the C-2000 alloy is resistant to both environments. The combined action of Mo and Cu (at 16% and 1.6% levels, respectively) gives the alloy excellent resistance to corrosion in reducing media, while high chromium content (23% wt) ensures resistance to corrosion in oxidizing media .

7.Hastelloy C2000 Application area

Hastelloy C2000 brings a lot of development potential to enhance manufacturing. When used in the original Ni-Cr-Mo alloy, its improved corrosion resistance can obtain longer service life of machinery and equipment under the same thickness of raw materials, and can also obtain more safety performance in more extreme cases. The improvement of corrosion resistance at all levels enables the machines and equipment to be used for various main purposes (reactors, heat exchangers, gate valves, pumps, etc.), resulting in a high rate of return. For example, the reactor can be incorporated into a sulfuric acid mix and subsequently converted to another working standard for a sodium cyanide-based mix. Because C-2000 a variety of nickel-based alloy raw materials can be integrated into a variety of processing technology.

8.Hastelloy C2000 Other application areas

1. Chemical industry reactor, inverter

2. Heat Exchanger

3. Valves, pumps, towers and pipes

4. Pharmaceutical industry reactors and dryers

5. Flue gas desulfurization system