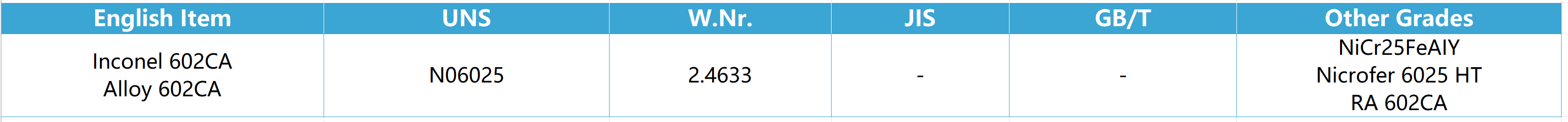

Inconel 602CA (Inconel 602CA) (N06025) (W.Nr.2.4633) (Alloy 602CA)(NiCr25FeAIY)(Nicrofer 6025 HT)(RA 602CA)

Available forms of Inconel 602CA

– Round bars、Wire、Forgings

– Sheet、Plate、Strip steel

– Seamless pipe and tube、Welded pipe and tube

– Pipe fittings and flanges

– Non-standard customised parts

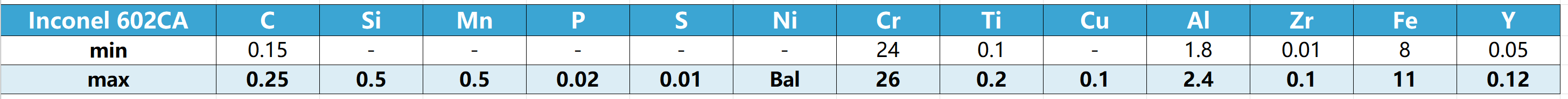

1.Inconel 602CA LIMITING CHEMICAL COMPOSITION, %

2.Inconel 602CA Introduction

INCONEL 602CA (UNS N06025 / W.Nr. 2.4633) is one of the most oxidation resistant nickel alloys available. Outstanding oxidation resistance is achieved through a high chromium content (25%) supplemented with aluminum (2.2%) and a microalloying addition of yttrium (0.1%). High chromium contents are known to be beneficial for resisting oxidation. The aluminum addition allows for the formation of a continuous homogenous self repairing AI2O3 subscale. The addition of yttrium improves the adhesion and spalling resistance of the chromium and aluminum oxide scales. The extremely low scaling rate of alloy 602CA makes it an excellent candidate for applications such as calciners, where minimal contamination from scaling is permissible. Extended exposure to methane (CH4), carbon monoxide (CO), and other carbon rich gases can lead to carburization. As heat resistant alloys absorb carbon, their ductility will gradually decrease. Alloys that are high in nickel, such as alloy 602CA possess excellent resistance to carburization attack8. Alloy 602CA forms a tenacious oxide scale, which provides increased protection from carburization. This protective scale impedes the carbon from being absorbed into the base metal.

3.Inconel 602CA MAJOR SPECIFICATIONS

Related products

-

High-Temperature Alloy

Nimonic 263-(Nimonic 263 )(Haynes 263) (Alloy 263)(N07263)(W.Nr.2.4650)(NCK20D)

Read more