inconel600 (inconel600)(UNS N06600) (W.Nr. 2.4816)(NiCr15Fe)

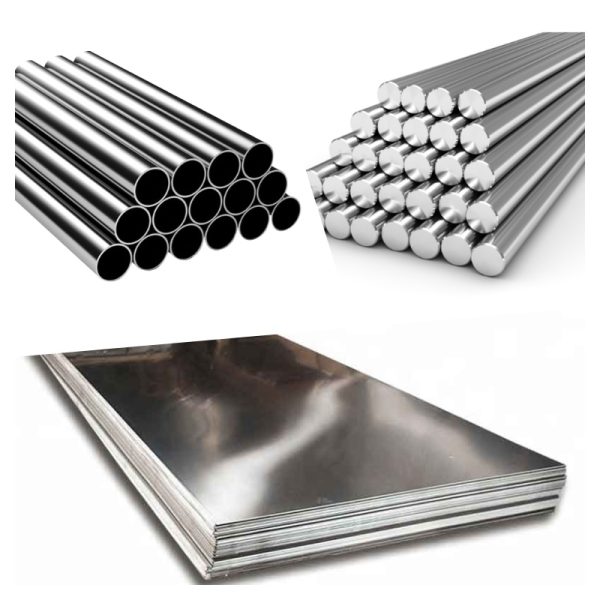

Available forms of inconel600

– Round bars、wire、forgings

– sheet、plate

– seamless pipe and tube、welded pipe and tube

– pipe fittings and flanges

– non-standard customised parts

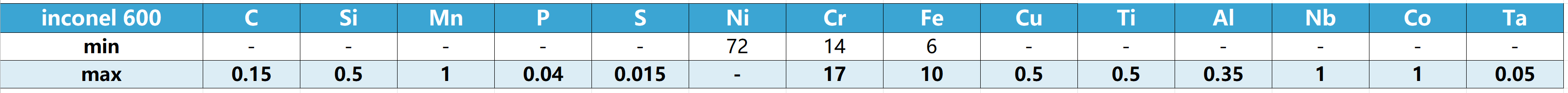

1.inconel600 LIMITING CHEMICAL COMPOSITION, %

2.inconel600 Introduction

A nickel-chromium alloy with good oxidation resistance at high temperatures and resistance to chloride-ion stress-corrosion cracking, corrosion by high-purity water and caustic corrosion. Used for furnace components, chemical and food processing, nuclear engineering and sparking electrodes.

3.inconel600 MAJOR SPECIFICATIONS

4.Inconel 600 PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3

………………………………………………………………0.306

g/cm3

………………………………………………………………. 8.47

Melting Range, °F

……………………………………………2470 – 2575

Melting Range,°C

……………………………………………1354 – 1413

Specific Heat, Btu/lb•°F

…………………………………………….0.106

J/kg•°C

………………………………………………….. 444

Curie Temperature, °F

………………………………………………… -192

Curie Temperature,°C

………………………………………………… -124

Permeability at 200 Oersted (15.9 kA/m)

………………..1.010

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F

…….. 7.4

21 – 93°C, μm/m •°C

………… 13.3

Thermal Conductivity, Btu • in/ft2•h•°F

……………………… 103

W/m •°C

…………………………………… 14.9

Electrical Resistivity, ohm • circ mil/ft

…………………………. 620

μΩ•m

………………………………………… 1.03

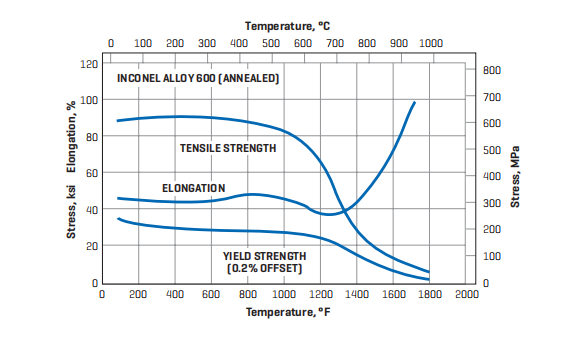

5.Inconel 600 TYPICAL MECHANICAL PROPERTIES

(Annealed)

Tensile Strength, ksi

…………………………………………………………95

MPa

…………………………………………………… 655

Yield Strength (0.2% Offset), ksi

…………………………………….45

MPa

………………………………. 310

Elongation, %

……………………………………………………………………40

Related products

-

High-Temperature Alloy

Incoloy 800 (Incoloy 800 )(UNS N08800) (W.Nr. 1.4876)(NCF 800)(X10NiCrAlTi 32-20)

Read more