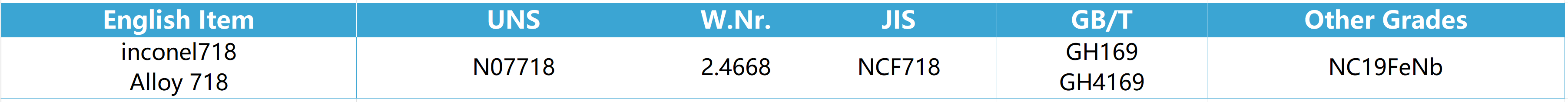

inconel718 (inconel718 )(UNS N07718) (W.Nr. 2.4668)(NC19FeNb)

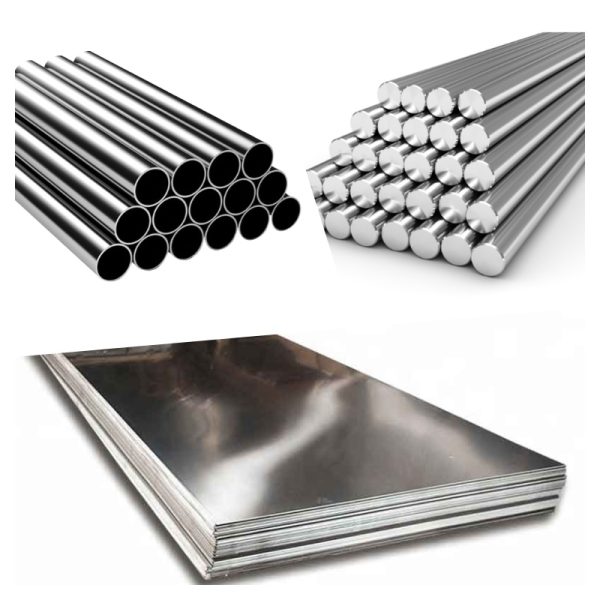

Available forms of inconel718

– Round bars、wire、forgings

– sheet、plate

– seamless pipe and tube、welded pipe and tube

– pipe fittings and flanges

– non-standard customised parts

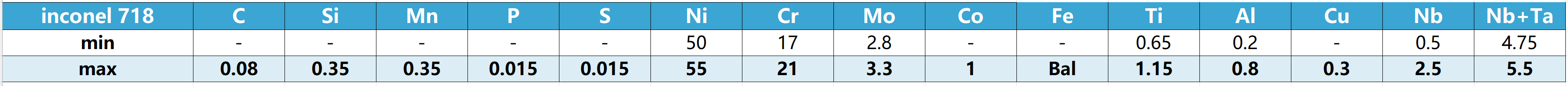

1.inconel718 LIMITING CHEMICAL COMPOSITION, %

2.inconel718 Introduction

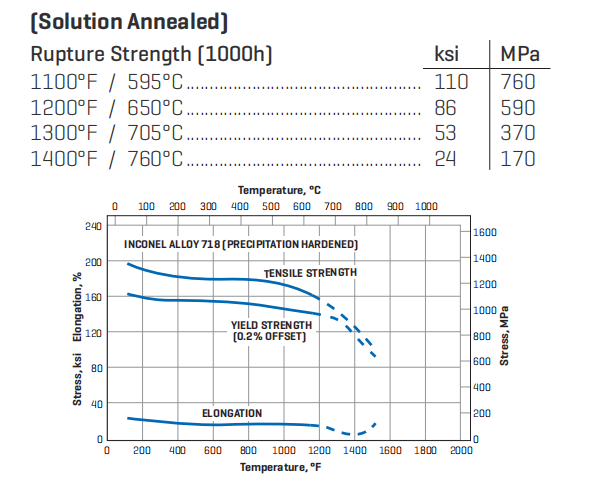

Inconel alloy 718 is a precipitation-hardenable nickel-chromium alloy also containing significant amounts of iron, niobium and molybdenum along with lesser amounts of aluminum and titanium. It combines corrosion resistance and high strength with outstanding weldability, including resistance to post-weld cracking. The alloy has excellent creep-rupture strength at temperatures to 1300°F (700°C). Used in gas turbines, rocket motors, spacecraft, nuclear reactors, pumps and tooling. INCONEL alloy 718SPF is a special version designed for superplastic forming.

3.inconel718 MAJOR SPECIFICATIONS

4.inconel 718 PHYSICAL CONSTANTS AND THERMAL PROPERTIES

Density, Ib/in3

……………………………………………………………….0.296

g/cm3

………………………………………………………………. 8.19

Melting Point, °F

……………………………………………..2300 – 2437

Melting Point, °C

……………………………………………..1260 – 1336

Specific Heat, Btu/lb •°F

…………………………………………….0.104

J/kg •°C

…………………………………………………. 435

Curie Temperature, °F

…………………………………………………. -170

Curie Temperature, °C

………………………………………………… -112

Permeability at 200 Oersted (15.9 kA/m)

…………….. 1.0011

Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F

…….. 7.2

21 – 93°C, μm/m •°C

………… 13.0

Thermal Conductivity, Btu • in/ft2• h•°F

…………………………79

W/m•°C

…………………………………… 11.4

Electrical Resistivity, ohm • circ mil/ft

……………………….. 751

μΩ•m

………………………………………… 1.25

5.Inconel 718 TYPICAL MECHANICAL PROPERTIES

Related products

-

High-Temperature Alloy

Inconel 686 (Inconel 686) (N06686) (W.Nr.2.4606) (Alloy 686)(NS3309)(NiCr21Mo16W)

Read more